Workshop Overview

cable production line

Mobile phone cables use materials like polyester fiber, copper core, hub, rubber, and nylon. These materials undergo safety and quality tests before production. Copper wires are wound to create the core, covered with PVC or TPE through injection molding. Each cable requires 4-6 cores, which are then wound and covered with TPE or nylon for further processing.

mould warehouse

This is our warehouse of terminal connector moulds. These moulds are used for injection molding between connectors and wires. The mould design determines the shaping style. With independently developed moulds, we can register design patents for the data cable. The cost of producing one mould typically ranges from $300 to $700. If your customized order quantity meets our Minimum Order Quantity (MOQ), we will waive the mould fee.

automatic production line

This is our automatic gluing machine. Before gluing, the machine will cut off a portion of the wire end and expose the copper of the cable, connect the cords with connector and glue them together.

Connector Soldering

After gluing the connector, the next step is soldering using tin. The data cable is then tested to ensure a reliable connection and proper transmission. Skilled and experienced soldering is essential to guarantee the quality and stability of the soldering points. Improper soldering can lead to data transmission interruptions, unstable signals, or cable damage.

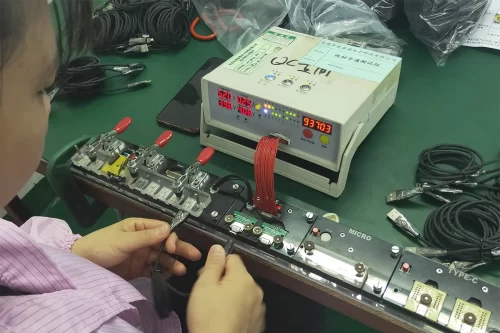

wire conductivity tester

The wire conductivity tester is used to test the correct connection and continuity between cables and connectors, ensuring that data cables can transmit data and charge properly. We test every single data cable to guarantee the quality of every product.

Connector Mould Injection

Upon placing the data cable connector into the mold, the injection molding machine injects molten plastic into the pre-designed mold cavity, effectively securing the cable and connector and shaping them into a specific form. Thanks to this plastic enclosure, the data cable connector becomes highly durable, capable of enduring thousands to tens of thousands of bending cycles.

horizontal pulling force test machine

The horizontal pull force test machine is used to assess the strength of data cable connectors. It applies a horizontal pulling force to the data cable connector until it separates from the cable, while recording the maximum tension value achieved. Typically, this value ranges from 15 kg·f to 50 kg·f.

salt spray chamber

The salt spray chamber is used to test the corrosion level of data cables and connectors in a specific concentration of salt fog environment.Cales are placed inside the chamber, and the salt spray is directed at them for a specified duration. After the test period, the specimens are examined for signs of corrosion, such as rust, blistering, or other deterioration.

cable bending tester

Cable bending tester is used to assess the durability and performance of mobile phone cables, as well as other types of cables used in various electronic devices. The primary purpose of this tester is to simulate real-world conditions and evaluate the cable’s ability to withstand repetitive bending and flexing movements, which are common in everyday use.